Upgrade – Vacuum Loader

Improve your loading system

Description

The vacuum gripping system for loading pin and unloading gripper (option) allows for a faster and more secure loading

and unloading of rotationally symmetrical workpieces. The system is specially equipped with sensors to monitor

the loading- and unloading-tools. A special crash sensor is mounted on the loading tool, replacing the original oil jet in the front of the chuck that is notoriously difficult to adjust and maintain. The simple, low-maintenance vacuum design is available for retrofit on all Nomyline and U88-machines that are equipped with internal loading systems.

Customer benefits:

• Reduction of cycletime by cutting downtime

• Increases production output (parts per hour)

• Reduces maintenance time – Periodic O-ring exchange is no longer necessary

• Simplifies maintenance and operation by virtue of its clean and simple design

Case study

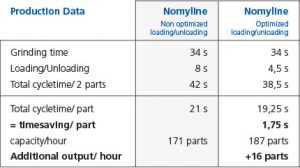

This example is based on our experience with similar upgrades at customer sites and shows production figures for typical

parts both before and after the modification. As illustrated, the vacuum gripping system significantly reduces cycle time

and therefore increases production output.

Please note that these figures are will vary based on your specific production criteria. We will be pleased to provide a similar analysis at any time.