UVA LIDKÖPING is Sweden`s largest machine tool manufacturer. We specialise in the manufacture of precision grinding systems.

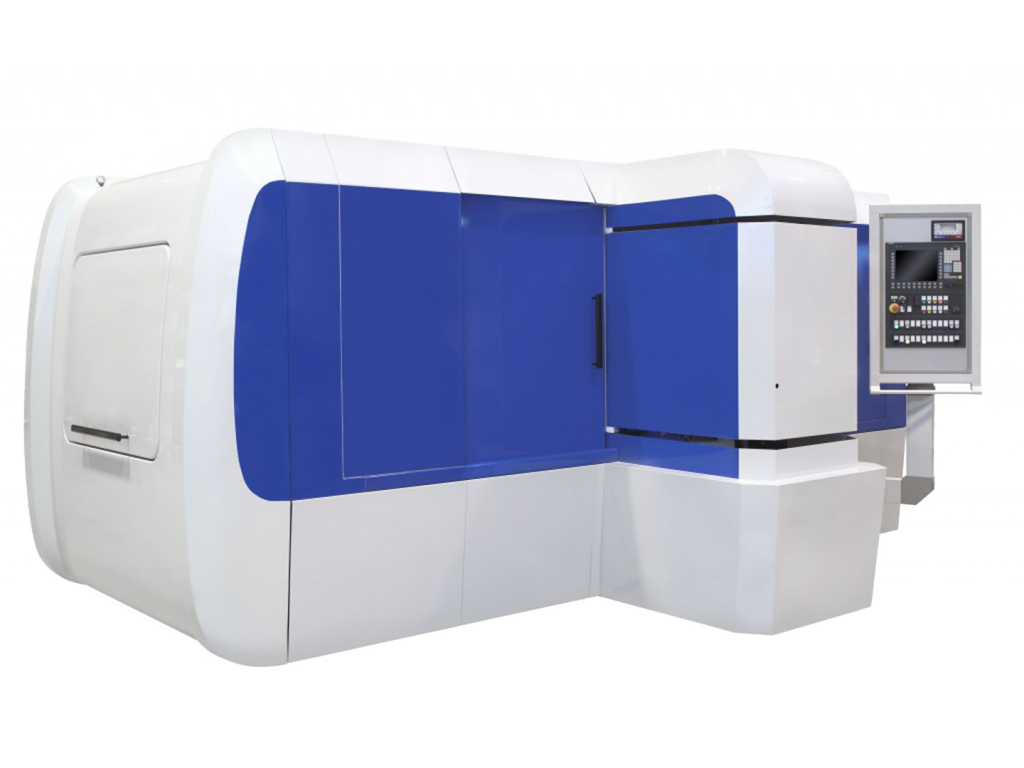

The LIDKÖPING SUUC grinding machine gives the user high output and quality. The SUUC platform can be set up for simultaneous Internal/External or Internal/Rib face grinding.

Our goal is to give you accuracy, efficiency and reliability through our products, our process knowledge and development, customer support and service. Through close cooperation with end-users, we ensure a correct and profitable solution for you, the customer.

Machine Concept

Grinding Operations Setup

SUUC machine is configurated for simultaneous, external and internal or internal and rib face grinding.

Hydrostatic Grinding Slides

Hydrostatic length- and cross slides, equipped with linear motors giving a feed rate of 1000 mm/s and a feed resolution of 0.01 μm.

Grinding Spindles

A wide range of high-requency spindles are available. Grinding wheel peripheral surface speeds up to 80 m/s.

Work Head

A unit consisting of work head spindle, driving plate, magnetic chuck or centric chuck and measuring unit. The work head is hydrostatic or roller bearing supported, equipped with a variable speed motor.

Gauging Method

In process electronic gauging.

Chucking Principle

Shoe centerless with magnetic chucking.

Dressing

The units are fixed to the machine base and, as standard, equipped with rotating diamond disc, single point diamond, full profile diamond roller or hydrostatic radius dresser controlled by CNC path. Dressing is performed during work piece loading. The LIDKÖPING hydrostatic CNC radius dresser is generating the form by interpolation between the lenght and the cross slide. The torque motor in the dresser keeps the dressing tool perpendicular to the profile of the grinding wheel. This dressing concept gives a high flexibility with the possibility to dress radius, track form with end drop etc.

Control System

Control System, SIEMENS SINUMERIK ONE.

Simultaneous Internal / Rib Face

Simultaneous Internal / Rib Face Simultaneous Internal / External

Simultaneous Internal / External