UVA Customize

Modules to customize your UVA Nomyline

Modules to customize the machine to the customers’ application.

The UVA Nomyline components have been specially designed by

KMT in order to satisfy customers’ unique precision needs.

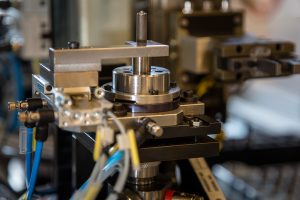

Pivoting spindle holder

Unique to UVA Nomyline. Proprietary technology that

compensates for quill bending, resulting in dramatically

higher grinding precision.

Grinding spindles

For grinding small bores and seats. Rotation speed of

45,000–150,000 rpm. Superb accuracy for superior

grinding quality.

Dressing

Proprietary grinding wheel dressing devices to insure

correct geometry and cutting characteristics.

Direct driven workhead

Torque motor direct driven workhead spindle. Supported by hydrostatic radial and axial bearings.

Stepless programmable speed from 0 to 3,000 rpm.

Measuring station

High resolution pneumatic measuring station for pre-process, post-process and match grinding.

Double cross slide

Linear motor driven & hydrostatic. Positioning repeatability

< 0,1 μm. Straightness over 30 mm < 0,1 μm.

Automatic loading

Standard option. Reduces cycle time and

improves component quality through extremely consistent loading.

Palett loading system – External loader with palett

handling system.

Automatic loading

Standard option. Reduces cycle time and

improves component quality through extremely consistent loading.

Chute loading system – External loader with chute

handling system.

Scanning equipment

The system provides monitoring and graphical illustration of the entire measured profile. By scanning a bore, machine compensation can be made in order to correct for form issues.